Laser Micromachining Technology

The Hi-Nano team boasts over two decades of focused development in laser micromachining technologies, enabling industry advancement. Our expertise shines in solving intricate micron-level challenges, particularly with ultra-hard materials like diamonds, sapphire, silicon carbide , lithium niobate, optical glass and beyond. Whether it's tailored machining or cutting-edge system production, rely on Hi-Nano for unmatched proficiency. Join us in this journey now!

Features:

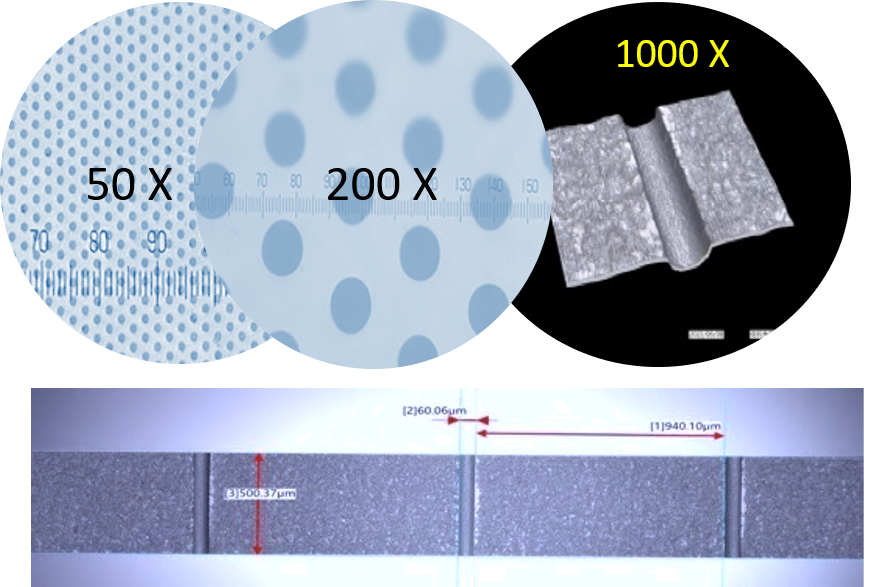

- Achieve micron-level precision with utmost accuracy.

- Employ a non-contact process to ensure minimal particle formation and maintain cleanliness.

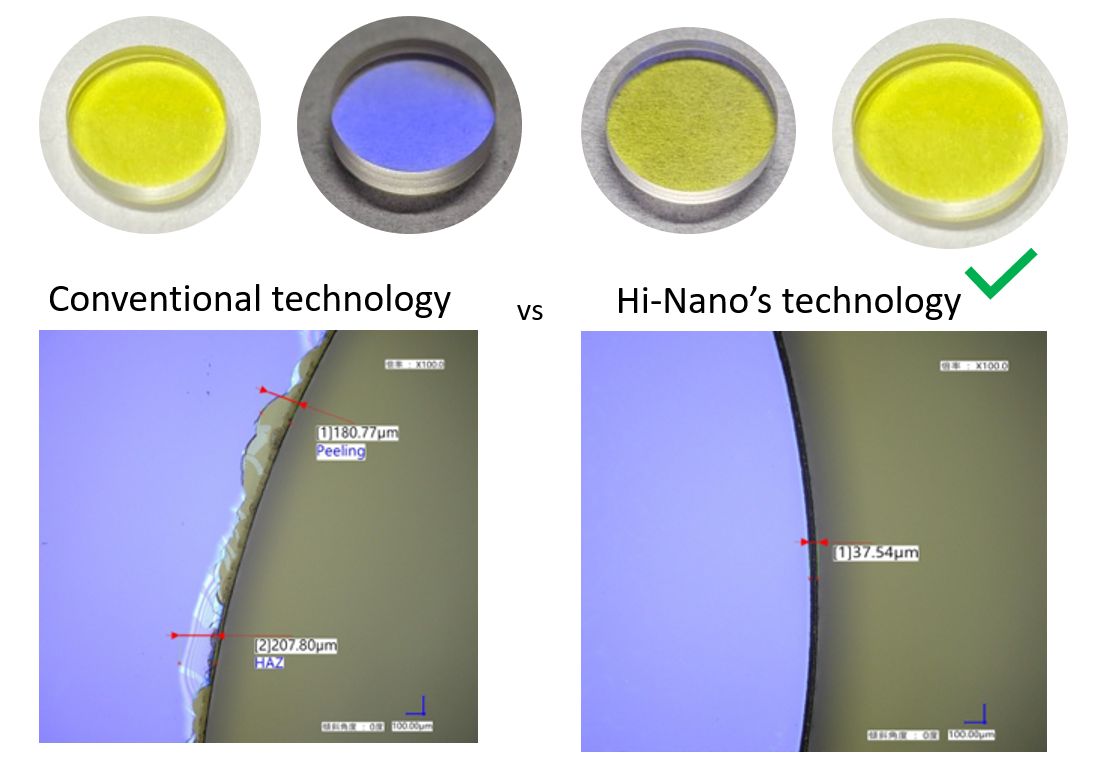

- Experience negligible heat-affected zone (HAZ) for pristine results.

- Minimize chipping and micro cracks during the cutting process.

Applications:

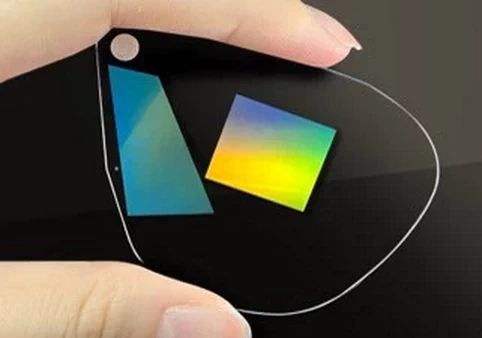

- Optical wafer dicing for precise manufacturing in the optics industry.

- Cutting AR and VR glasses with utmost precision.

- MEMS wafer dicing for micro-electromechanical systems.

- Cutting coated lenses with exceptional accuracy.

- Laminated optics cutting for seamless integration of optical components.

- Optical sensor cutting for intricate sensor devices.

Features:

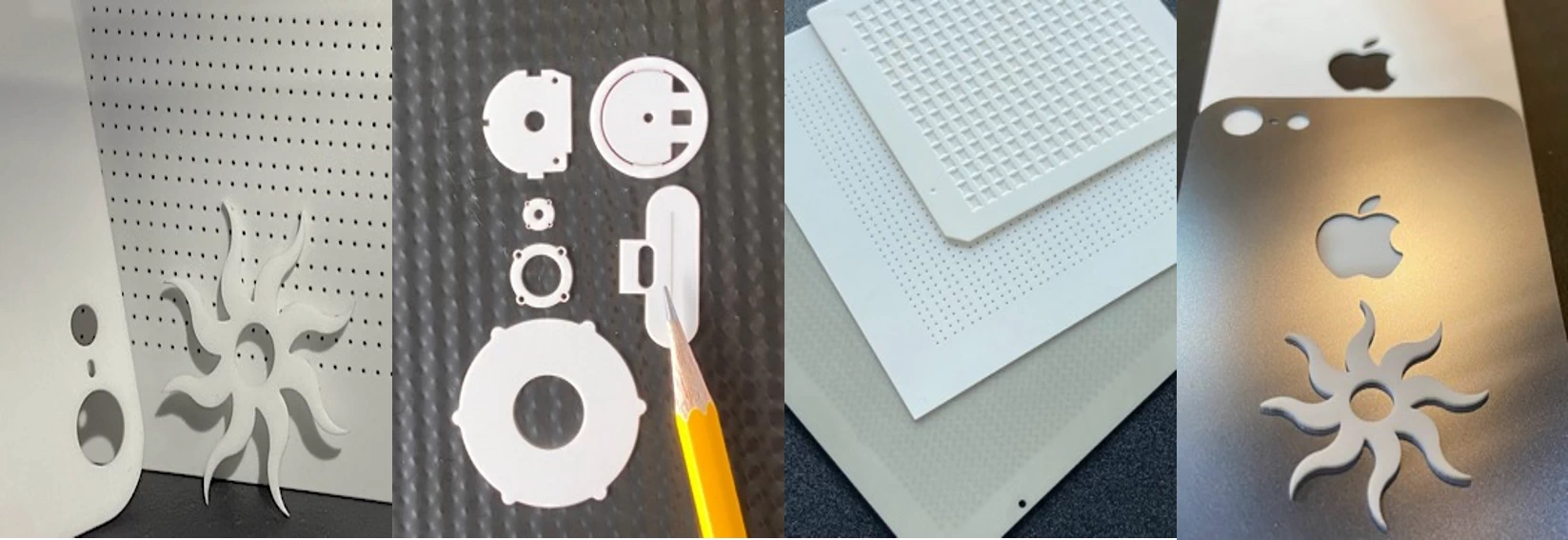

- Capable of cutting both straight lines and free shapes with precision.

- Accommodates a wide range of glass thicknesses, from ultra-thin and bendable to ultra-thick glass.

- Enables cutting and drilling of various optical glass types with exceptional accuracy.

- Delivers high cutting quality for coated lenses, ensuring superior results.

Applications:

- Cover glass and view windows for electronic devices and displays.

- Optical sensors, providing accurate and reliable sensing capabilities.

- Glass substrates for diverse electronic and optical applications.

- Car mirrors, ensuring safety and clarity for drivers.

- Optical lenses, crafting lenses with precision and efficiency.

- Glass components for various industrial and consumer products.

- Laminated glass for enhanced durability and functionality in specialized applications.

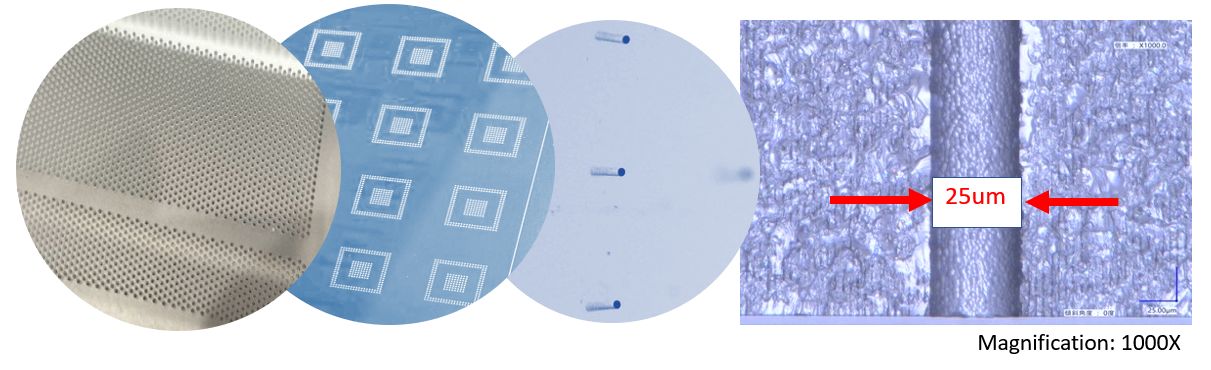

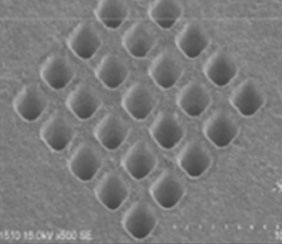

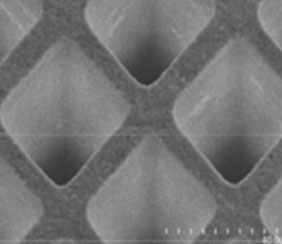

Features:

- Holes available in straight or hourglass shapes.

- High aspect ratio capabilities, extending up to 1:20.

- Achievable minimum micro hole size, with diameters as small as 20 micrometers.

- Remarkable precision levels for consistent results.

- Cost-effective manufacturing process.

Applications:

- Miniaturized cameras and sensors for smartphones and wearables.

- Endoscopes and minimally invasive medical devices for internal imaging and diagnostics.

- Micro optics for coupling light signals in compact optical communication devices.

- Miniature Lidar systems for robotics, drones, and autonomous vehicles.

- Optical sensors for fingerprint recognition and gesture control.

- Compact vision systems.

- Smart glasses and AR devices.

- Mini. cameras and sensors for (UAVs) and drones.

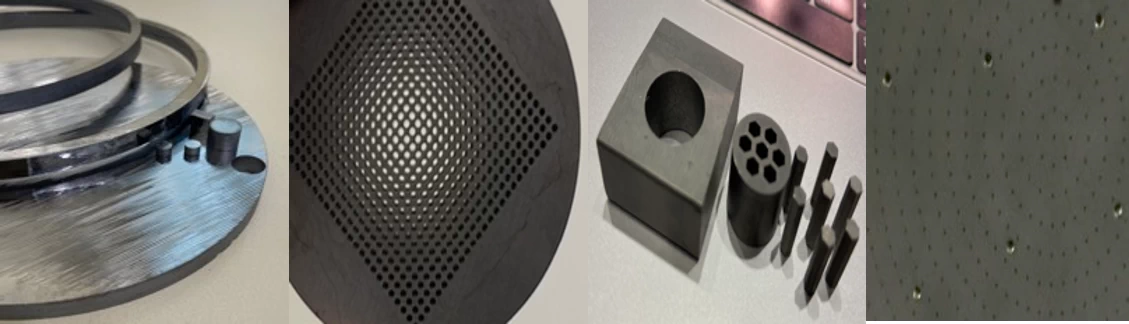

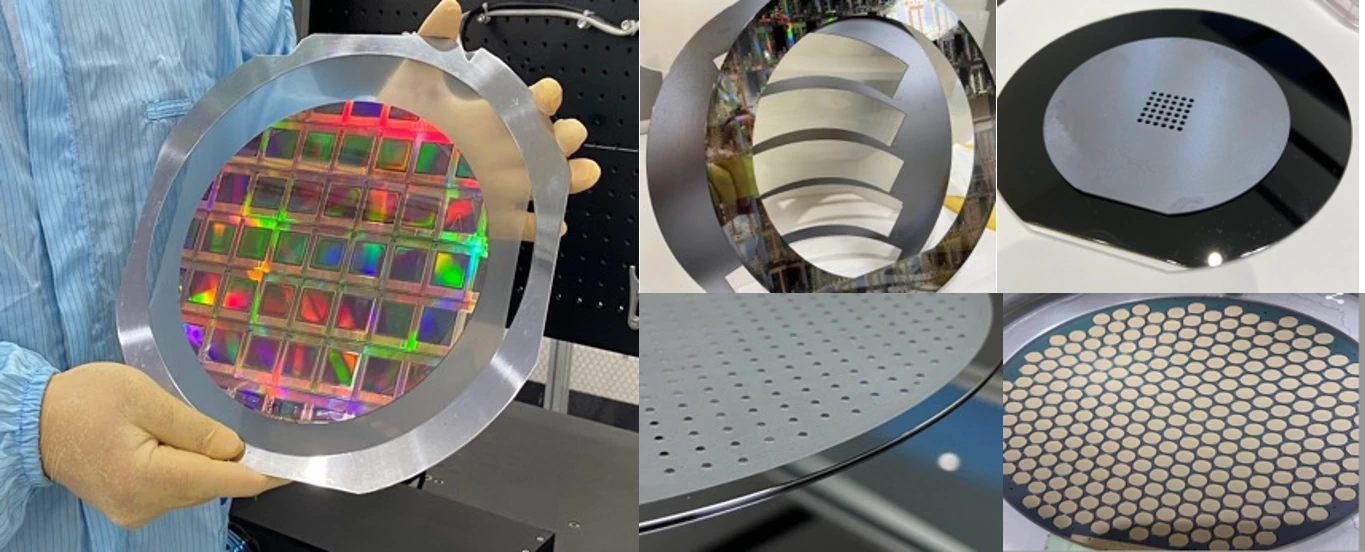

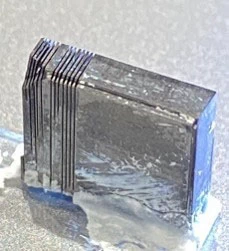

Applications:

- Employed as wafer chucks, susceptors, and carriers in the Chemical Vapor Deposition (CVD) and epitaxy processes for semiconductor fabrication equipment.

- Utilized as electrodes and components within dry etching equipment’s chambers and more.

- Integrated into aircraft brake disks to enhance performance.

- Utilized for mechanical components across diverse industries, underscoring its exceptional qualities of high temperature resistance, hardness, and lightweight characteristics.

Features:

- High Precision

- Minimal Material Loss

- Reduced Heat Affected Zone

- Processing of Complex Shapes

- Versatility

- Minimal Contamination

- High Throughput

- Easy Automation

- No Tool Wear

- Environmental Friendliness: No need for coolants or lubricants.

Applications:

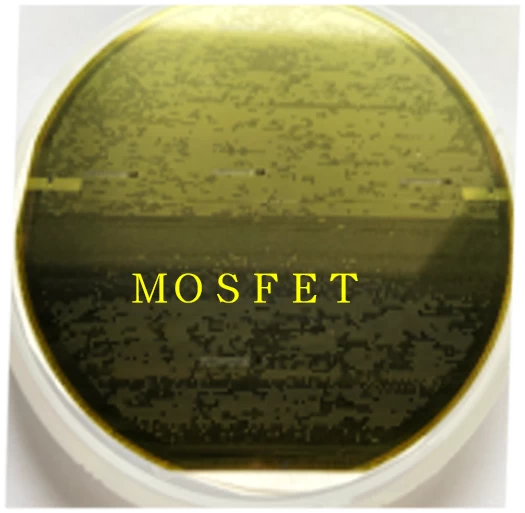

- Power Electronics: SiC is extensively used in power semiconductor devices.

- High-power laser diodes: used in communication and industrial processes.

- High Frequency Wireless Communication Devices.

- Aerospace and Defense

- Automotive: SiC-based inverters, diodes, MOSFETs, and IGBTs.

- Industrial Heating

- Seals and Bearings