Laser Micromachining Services

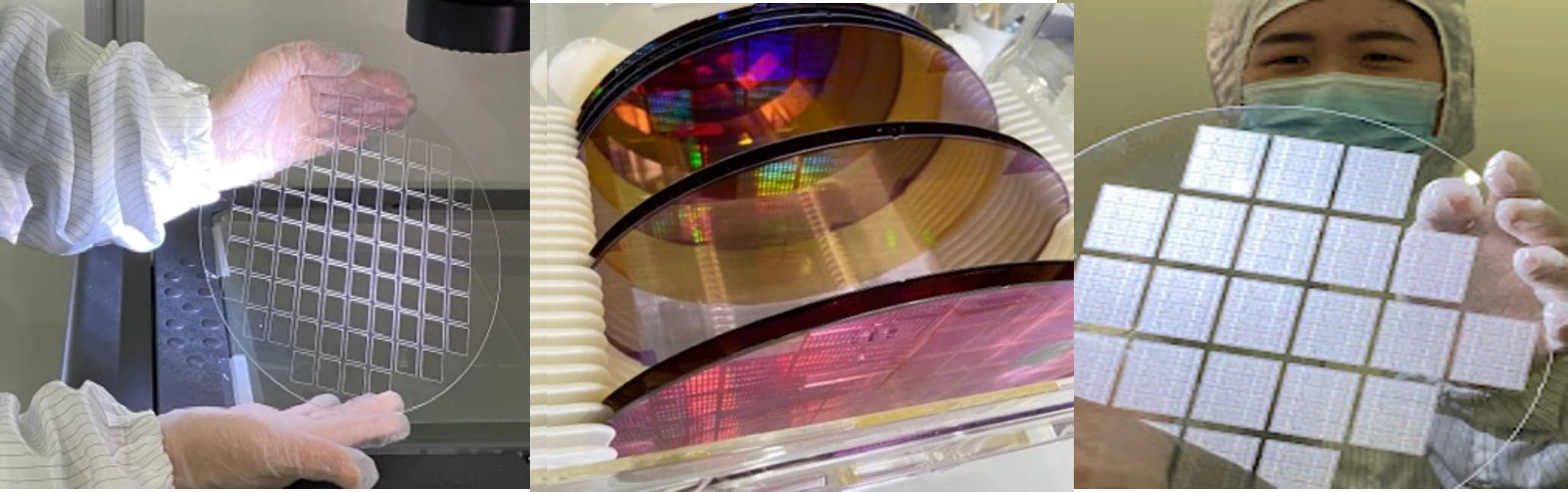

Major Markets:

- Semiconductor Industry : Enabling advanced 2.5D and 3D packaging.

- Telecommunications : TGV is crucial for high-performance components in telecommunications, supporting the demand for low-loss, faster and more reliable communication devices.

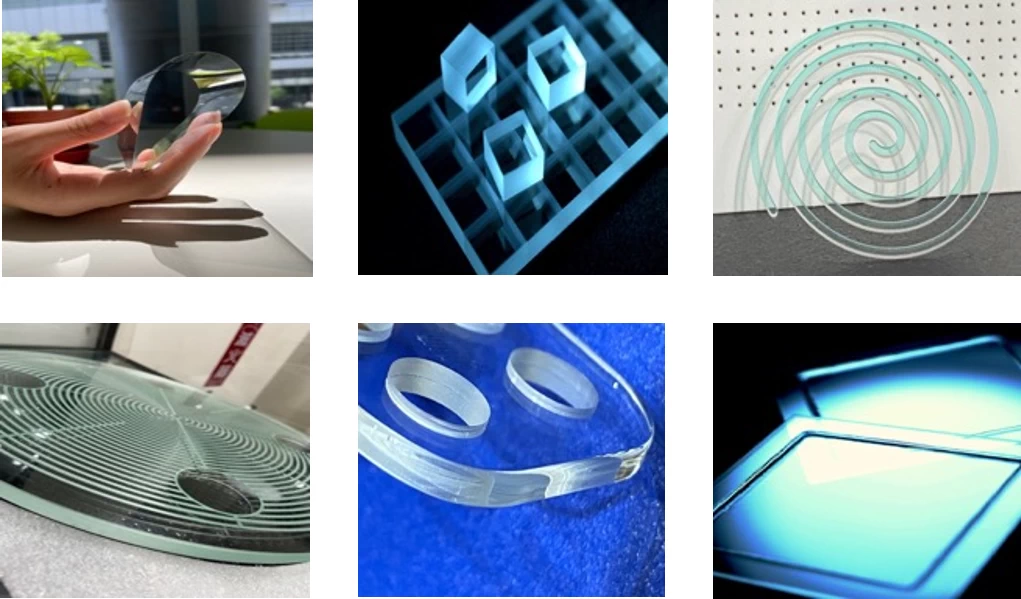

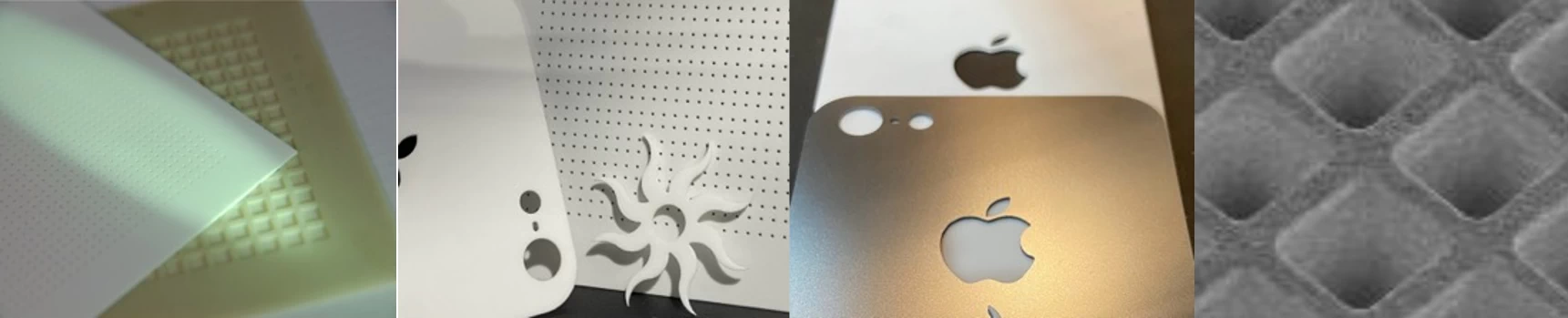

Custom Jobshop Services:

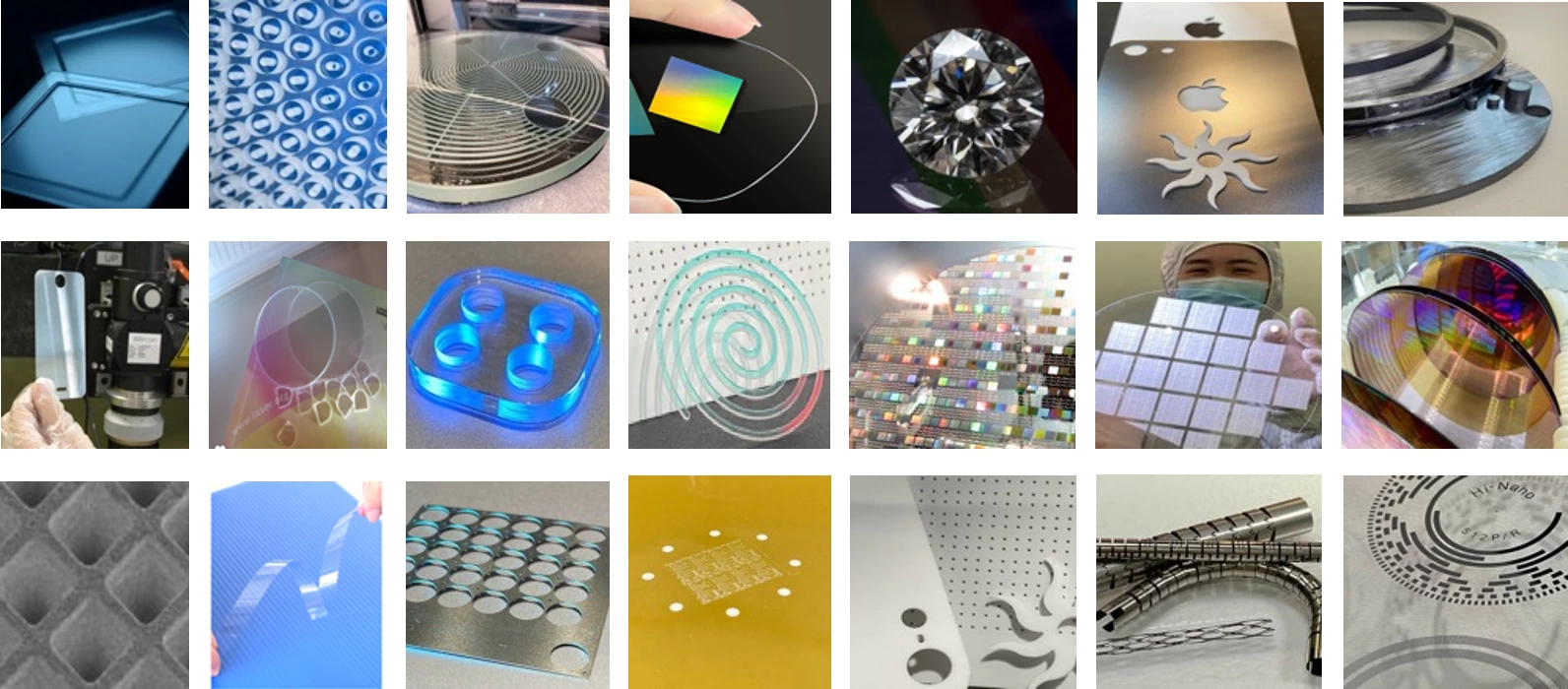

Applications:

- Ultra-thin ( 25um) glass cutting

- Thick-glass (10mm)cutting

- Spiral Glass cutting

- 10 mm thick glass chuck

- cutting and grooving

- Glass joining and polishing

- Capping bio-glass selective slimming.

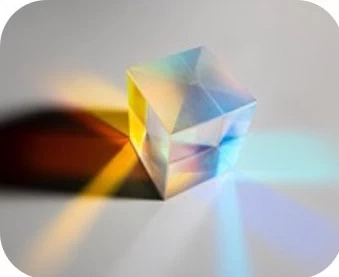

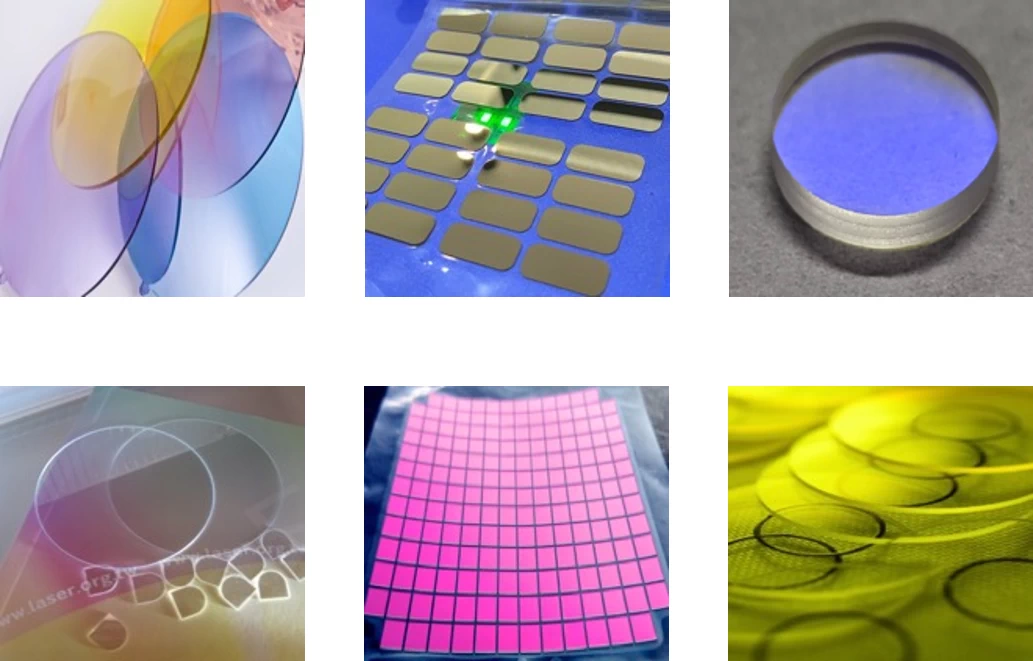

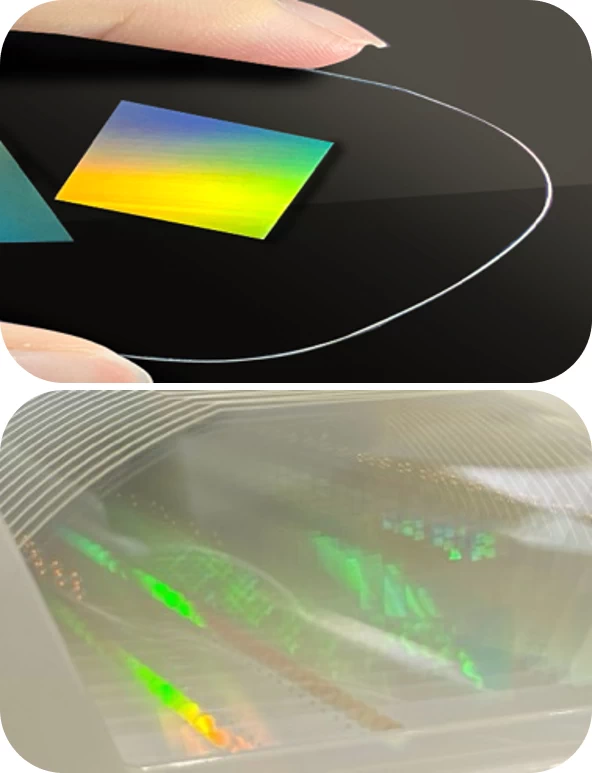

Applications:

- Band-Pass Filters

- Optical Sensors

- Micro Lens Array

- Lidar (Light Detection and Ranging)

- Anti-Reflect Lens

- Protective Windows

- Dichroic Filters

- Beam Splitters

- Polarizing Filters

- Dielectric Mirrors

- IR (Infrared) Windows

- UV (Ultraviolet) Filters

- Gradient Index (GRIN) Lenses

- Sapphire Lenses

- Diamond Lenses

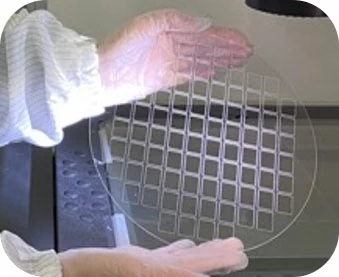

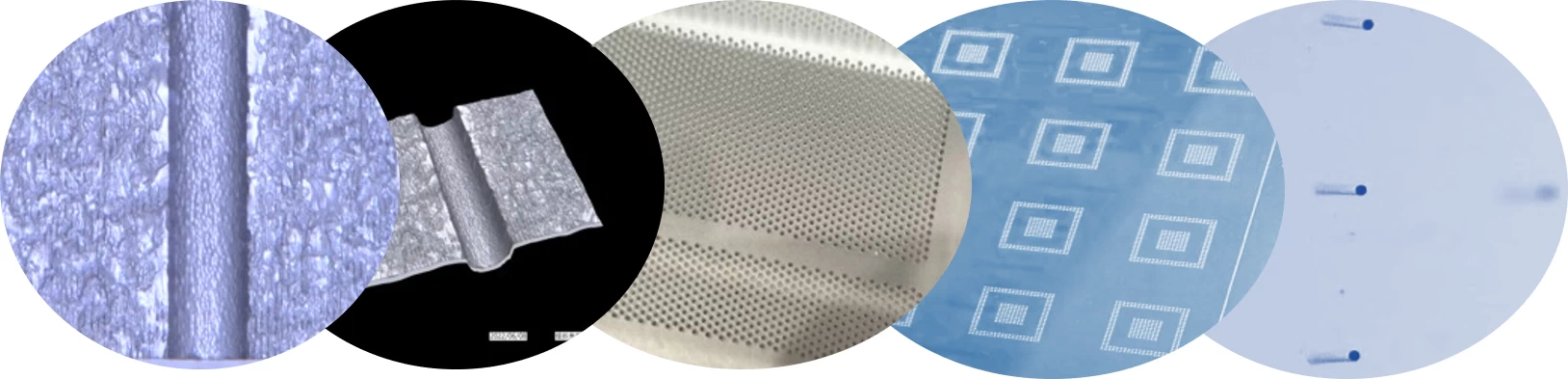

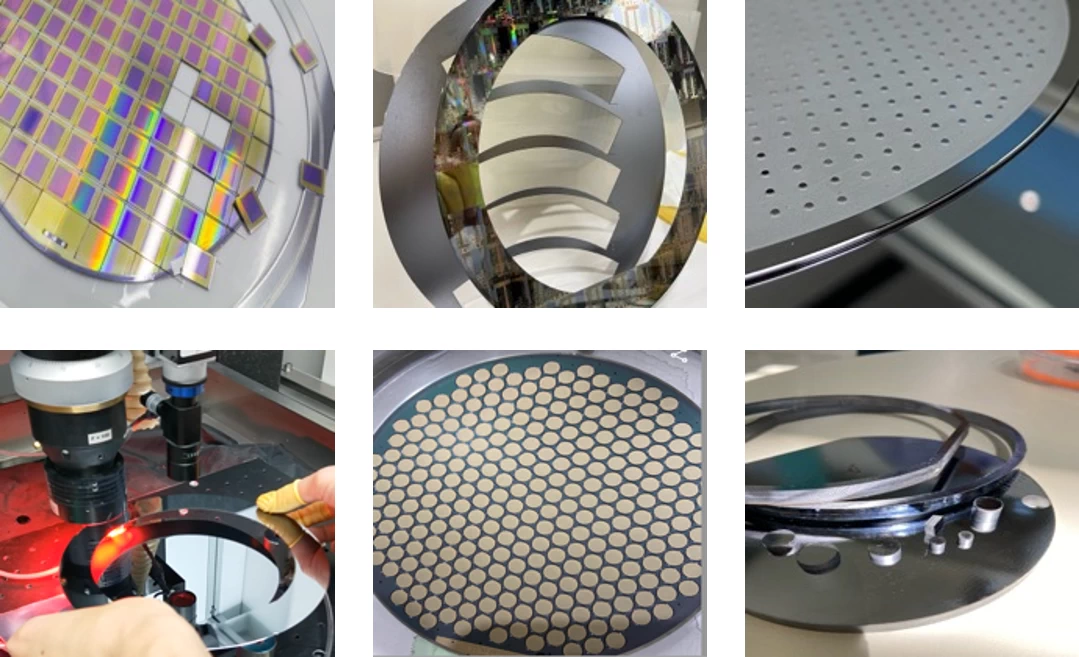

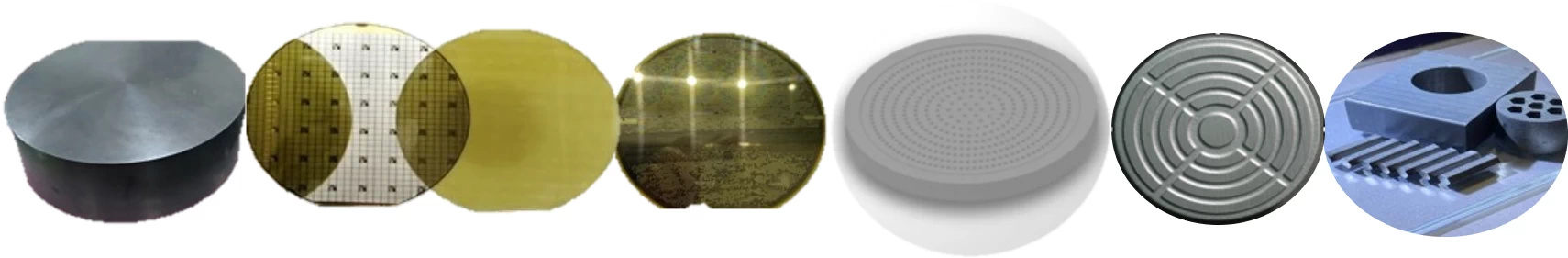

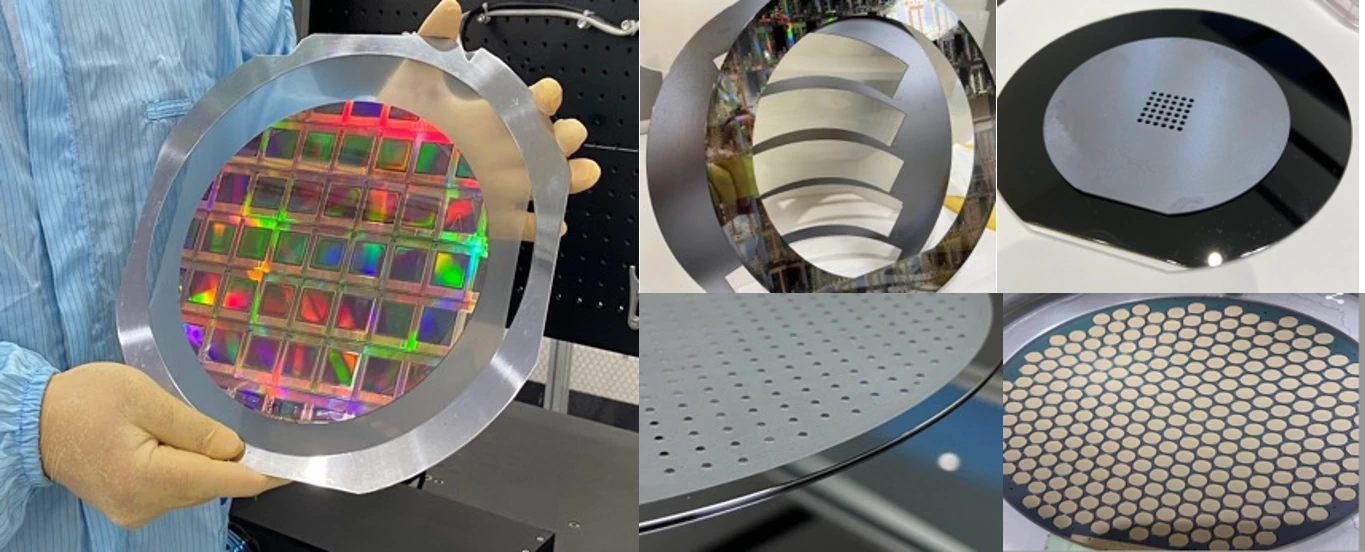

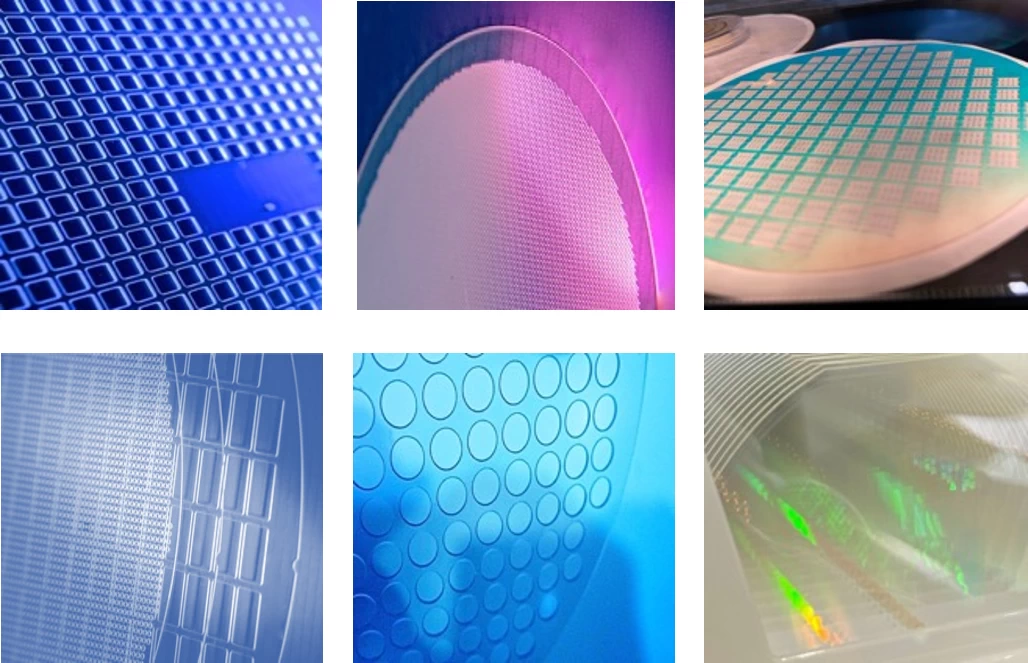

Applications:

- Wafer downsizing

- Low-k wafer dicing

- Ultra-thin wafer dicing

- Micro mirror array wafer dicing

- MEMS wafer with moving parts

- Nano structured optical wafers

- Taiko ring wafer dicing

- Muti-project wafer selective dicing

- Gpp Round dice power devices dicing

- Raised dots wafer machining

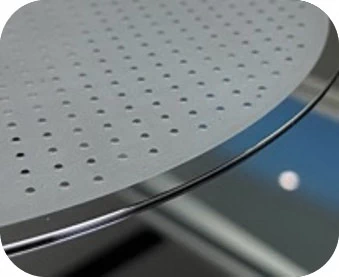

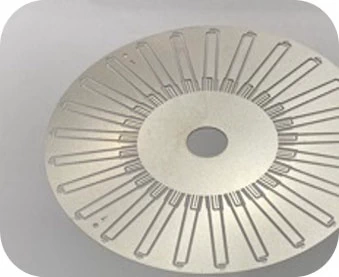

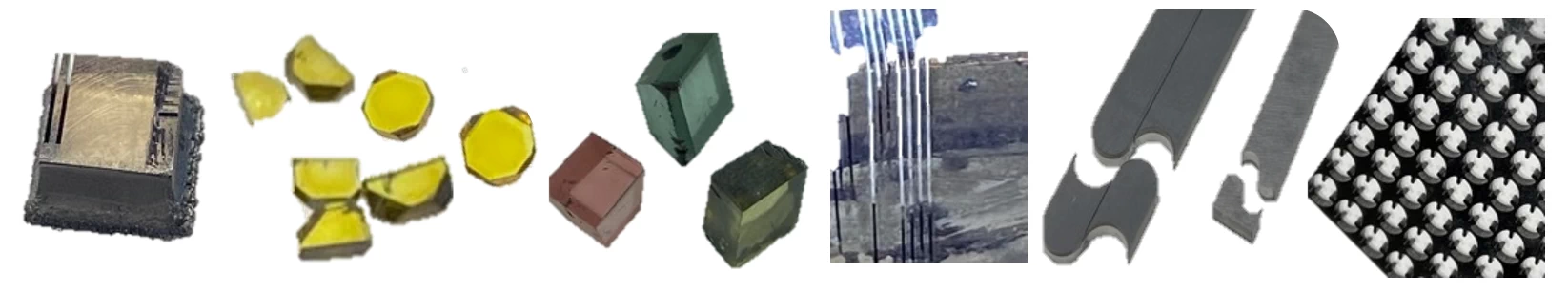

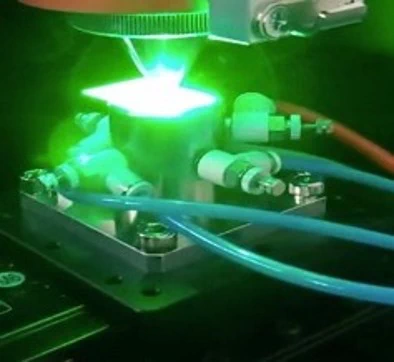

Laser machining for SiC ( Silicon Carbide )

SiC, a key material for next-generation semiconductors, boasts hardness just below diamond, making it extremely challenging to machine. In response, Hi-Nano has pioneered laser machining solutions tailored for SiC wafers, covering tasks like:

Ingot Slicing, Freeform Dicing, Hole Drilling, Grooving, Surface Texturing, and more.

Additionally, Hi-Nano excels in machining thick sintered SiC to create essential tools and machine parts for semiconductor manufacturing equipment, including precision components like SiC wafer chuck tables, focus rings, and wafer carriers.

Notably, Hi-Nano’s approach exclusively relies on laser non-contact processes, eliminating tool wear issues. This unique attribute makes it ideal for applications requiring the precise drilling of numerous tiny holes, such as in SiC shower heads.

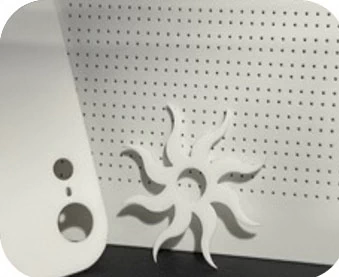

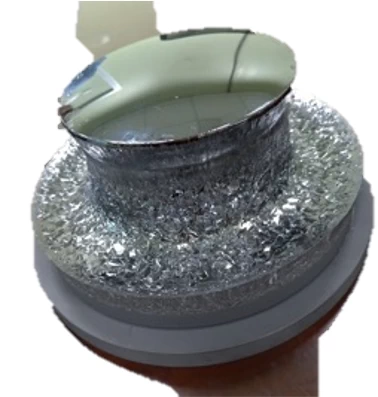

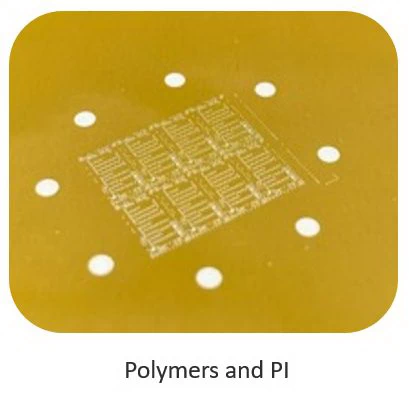

Polymers and PI

Hi-Nano uses versatile laser systems for precise processing of polyimide (PI) and similar flexible materials in microelectronics, FPCBs, RDL, and IC probe card isolation layers. These systems perform tasks like free-shape cutting and micro-hole drilling without heat-affected zones.

Laser processing typically follows electronic component mounting, often with other substrates. Polyimides, commonly in thin, flexible circuit boards, also serve in energy storage and alternative energy insulation.

Their exceptional properties, including resistance to extreme temperatures (-256° to 400°C), make them widely used in aerospace. Kapton films, a type of polyimide, can be laminated, metallized, or coated with adhesives.

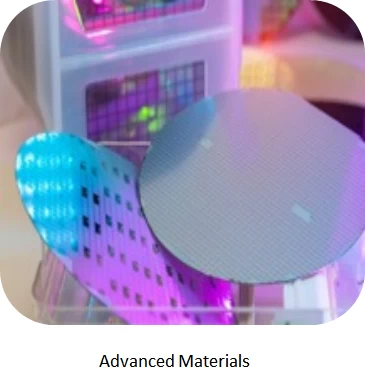

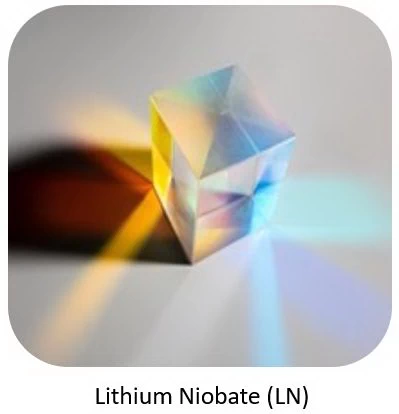

Advanced Materials

Recently, driven by the substantial market demand for artificial intelligence, the Internet of Things, and advancements in 5G, 6G, and LEO communications, a large amount of cutting-edge materials for optical, communication, and IC 3D packaging continues to emerge. This includes multi-layer composite functional materials, presenting challenges beyond the scope of conventional methods.

Hi-Nano has consistently assisted customers in addressing diverse specialized processing issues, accumulating extensive expertise in precision processing over the years.

Consequently, when faced with materials that are challenging to machine, Hi-Nano may already have effective solutions.

Simply reach out to Hi-Nano – your challenging issues might find a resolution.