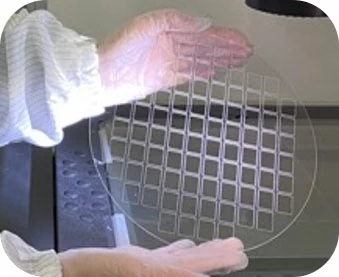

Laser Micromachining Services

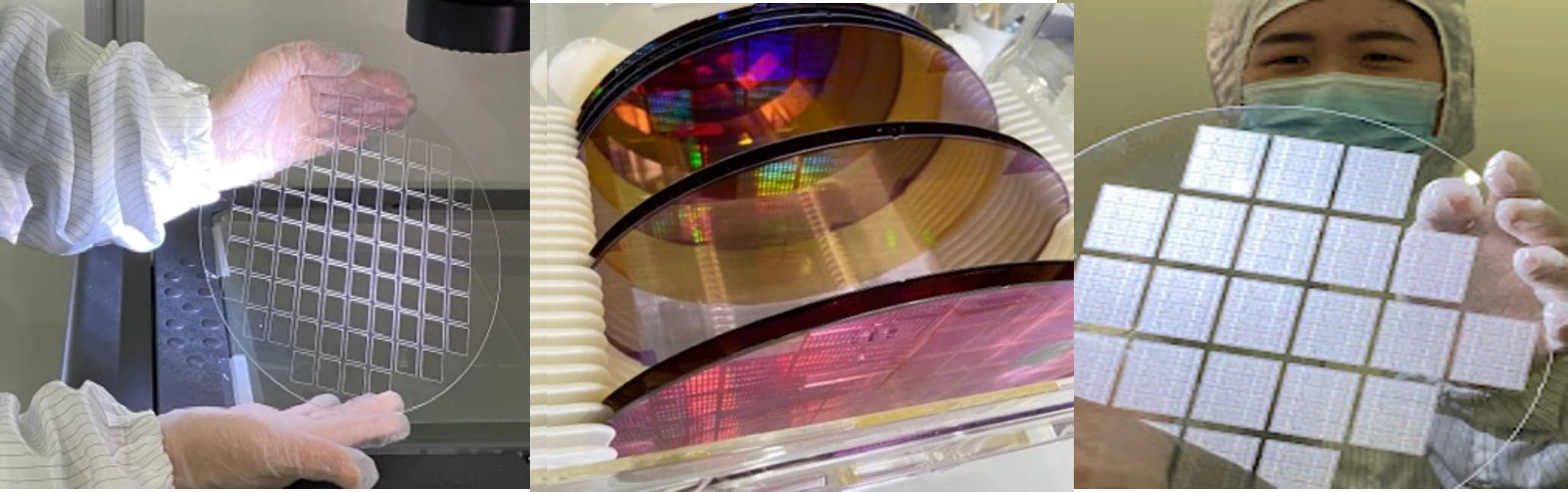

Hi-Nano specializes in delivering cutting-edge solutions for challenging high-precision machining needs across a wide range of materials. Our state-of-the-art technology and expert team are dedicated to providing exceptional results for our customers.

Major Markets:

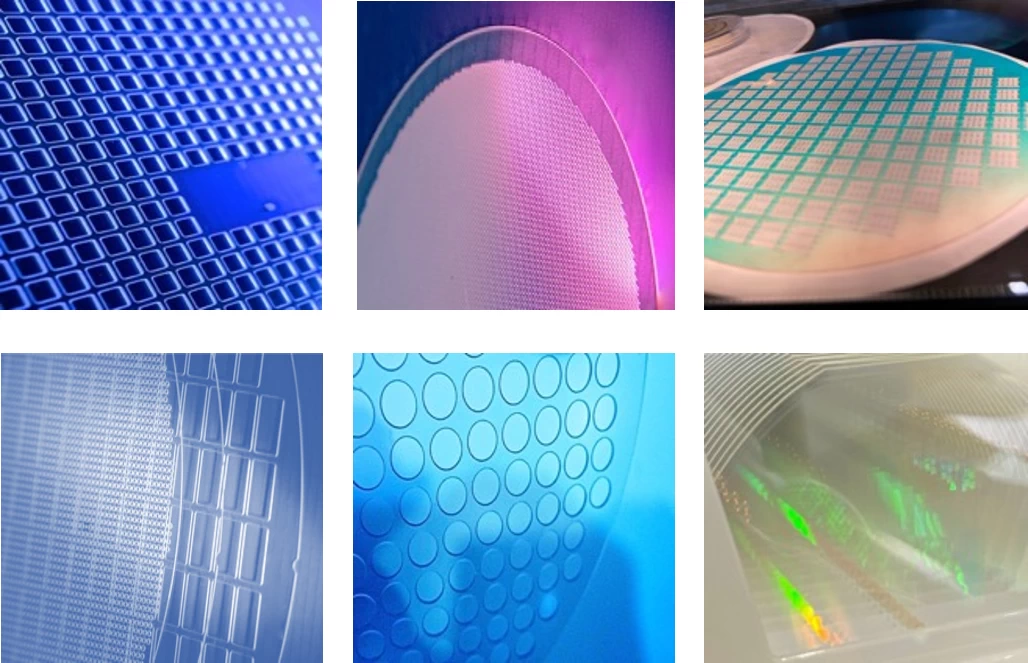

- Semiconductor Industry : Enabling advanced 2.5D and 3D packaging.

- Telecommunications : TGV is crucial for high-performance components in telecommunications, supporting the demand for low-loss, faster and more reliable communication devices.

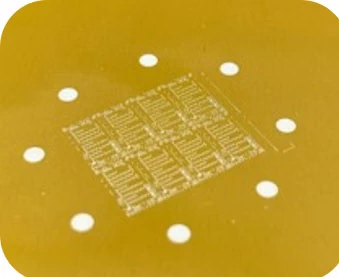

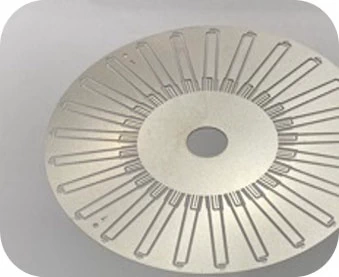

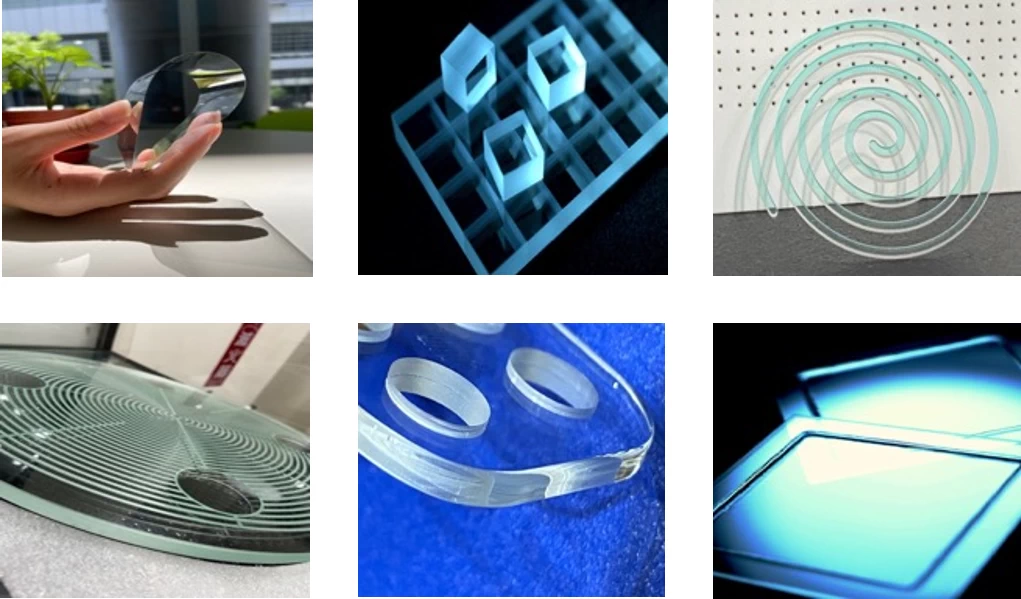

Custom Jobshop Services:

We provide custom jobshop services to meet the unique needs of our clients. Whether you require prototype development or large-scale production, our team is ready to deliver excellence.

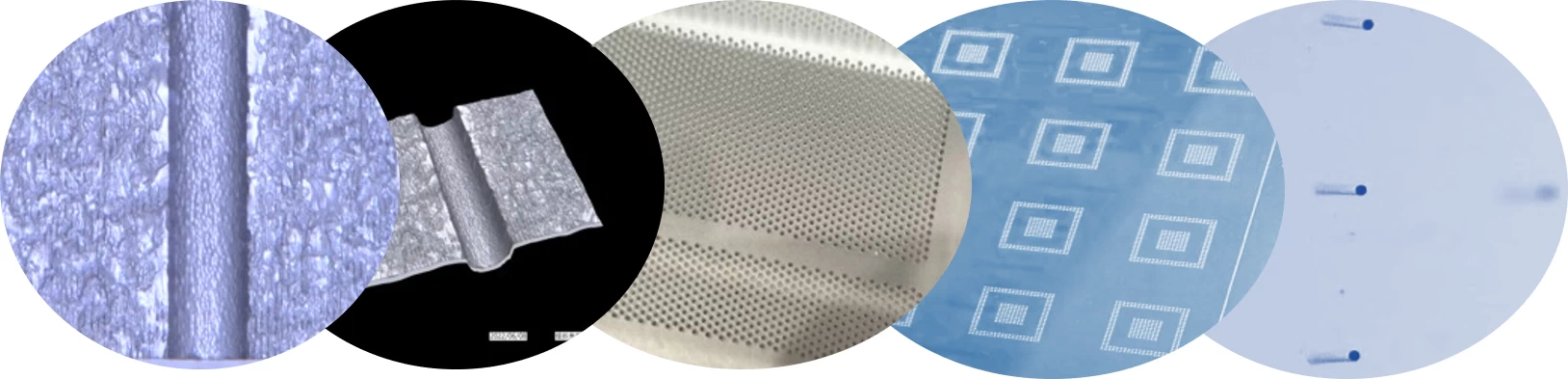

Applications:

- Ultra-thin ( 25um) glass cutting

- Thick-glass (10mm)cutting

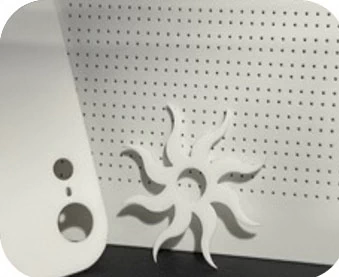

- Spiral Glass cutting

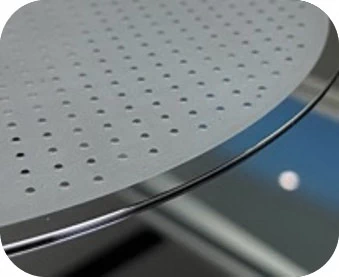

- 10 mm thick glass chuck

- cutting and grooving

- Glass joining and polishing

- Capping bio-glass selective slimming.

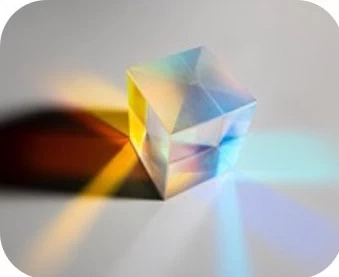

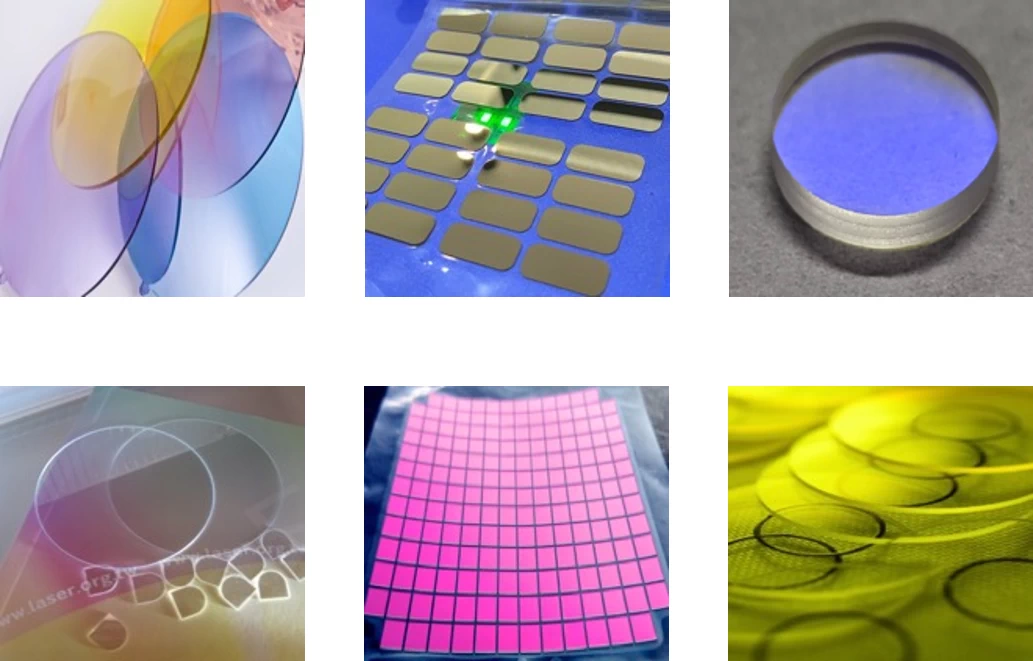

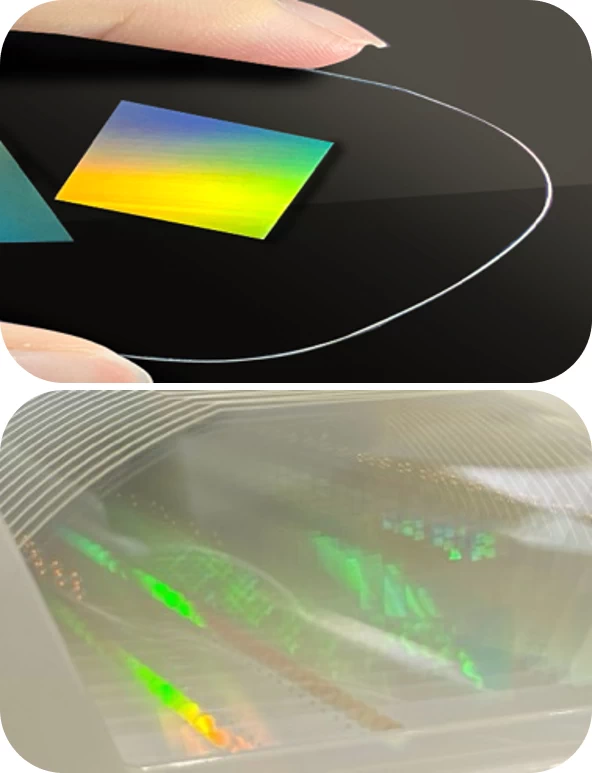

Applications:

- Band-Pass Filters

- Optical Sensors

- Micro Lens Array

- Lidar (Light Detection and Ranging)

- Anti-Reflect Lens

- Protective Windows

- Dichroic Filters

- Beam Splitters

- Polarizing Filters

- Dielectric Mirrors

- IR (Infrared) Windows

- UV (Ultraviolet) Filters

- Gradient Index (GRIN) Lenses

- Sapphire Lenses

- Diamond Lenses