Products

The UV-M6 engraver is a versatile tool for micro structuring, surface texturing, and industrial engraving on various materials. It includes a built-in marking and barcode generator for high-precision applications, accommodating text, photos, logos, and 1D/2D barcodes such as QR codes and data matrix, among others.

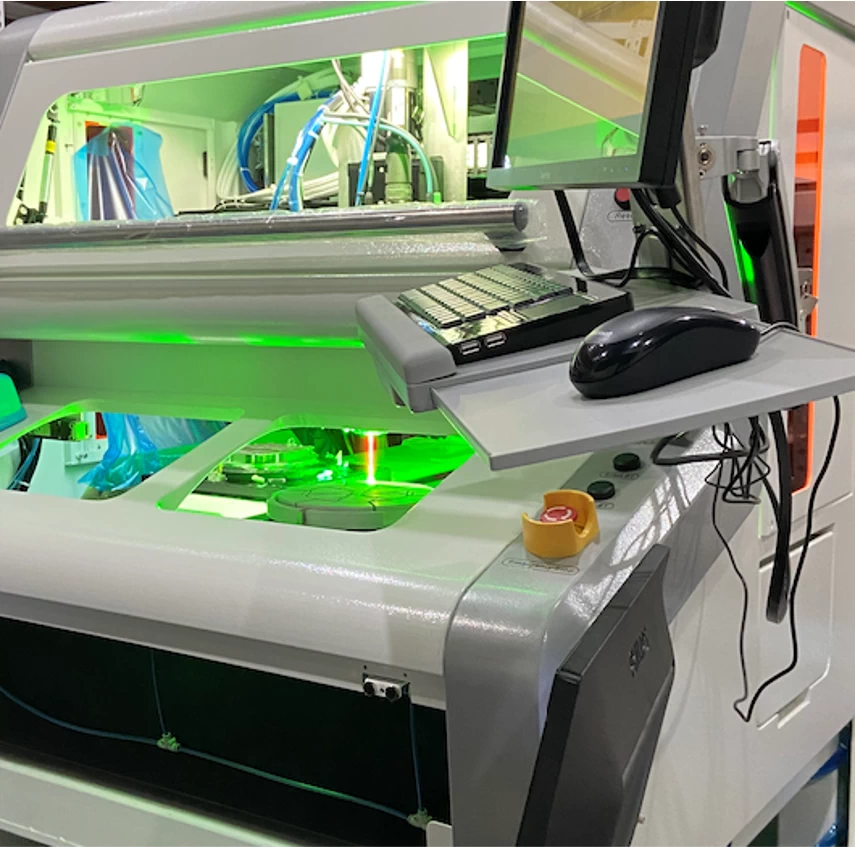

The SP2 employs a CO2 laser to quickly heat and cool along the existing cutting line, generating internal thermal stress to separate the glass. This non-contact process is suitable for optical glass wafer processing and is capable of handling both straight lines and curves

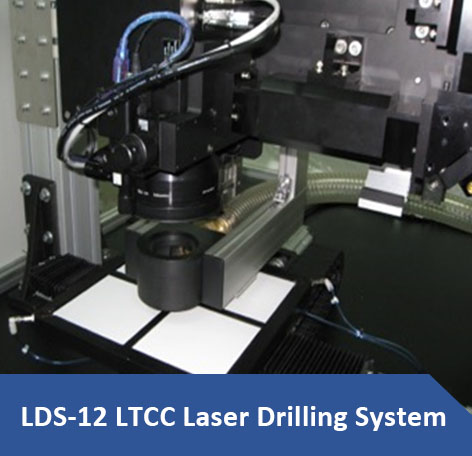

The LDS-12 is a semi-automatic laser machine specifically designed for high-speed hole drilling in ceramic substrates. It achieves clean and uniform interconnect holes with virtually no dross or burrs formation on the entrance and exit sides. The system is characterized by its compact design and cost-effectiveness.

The MicroVias-1000 is a high-speed laser perforation system designed for Green Tape (Unfired Ceramic). Despite operating at high scan speeds, it consistently maintains high hole quality that adheres to the stringent standards of electronic components.

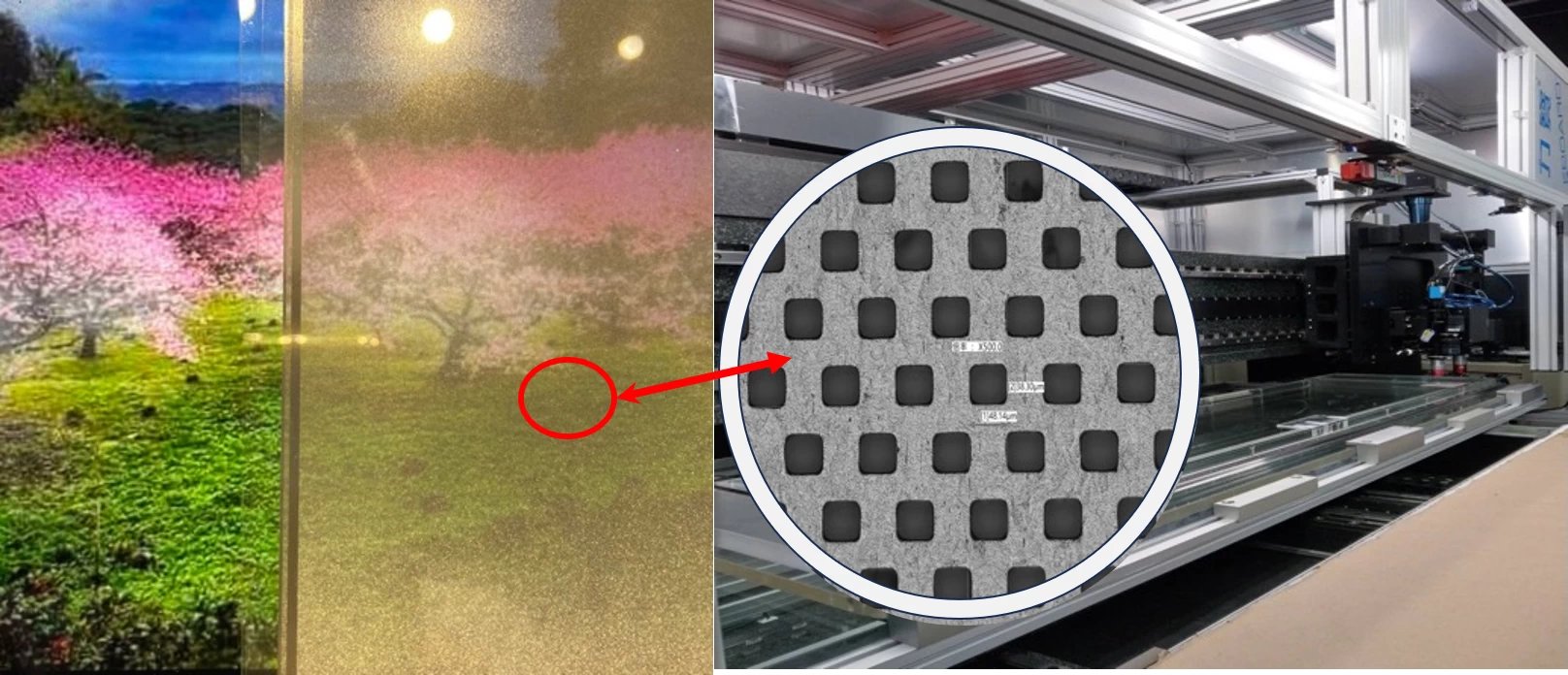

The AR-200A is an automated system for laser singulation, designed specifically for 8″ AR glass wafers, transitioning from cassettes to trays. The system seamlessly processes AR wafers into AR lenses. Given that the wafer incorporates nanostructured optical devices, the system adheres rigorously to SECS/GEM SEMI Standards in its design rules.